Features

- Interface to a single board computer based on an NEC V25 processor.

- Interface to a host PC via an RS-232 port.

- Interface to a natural gas flow meter, an additional RS-232 port.

- Optional third RS-232 interface for connecting existing calibration equipment or a reference meter.

- Digital temperature sensor and a temperature controlled environment (regulated oven) for the analogue portion of the board.

- 24-bit sigma-delta ADC for converting temperature and pressure information to digital form.

- Interface to a Platinum RTD temperature sensor.

- Interface to a Pressure transducer.

- Stepper motor driver with user-settable speed and Hall affect sensor for rotational speed measurement.

- Rotational counter for calibrating flow meter input shaft rotations.

- Software control and manual override controls of all stepper motor functions.

Description

The image at right is of a complete unit in operation. The unit is shown with a Mercury Instruments Mercor EC industrial gas flow meter being calibrated. Software running on the adjacent notebook PC is used to turn the wriggler on the meter and record temperature and pressure information. Not shown in the photo are the temperature and pressure sensors as well as the pressure vessel used for calibration.

In addition to the above hardware implemented features, the software running on a host PC properly accounts for supercompressability of Natural Gas as pressure and temperature vary. The system software also supports data logging so that a database can be maintained of calibration history. This database is expected to be maintained by the operator and be independent of other calibration units.

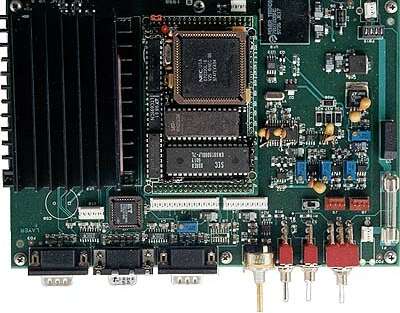

Although only the instrument hardware is shown at the top, the product is shipped as shown in the second photograph (laptop not included).

Inquiries

General inquiries regarding purchasing this product, designing and programming with the TERN embedded single board computer and/or design of measurement hardware can be directed to J-Tech Engineering. Please see the company info page for contact information.